|

The proud (!) new owner and the outfit on the trailer.

|

The sidecar is a single-seater with an aluminium skin on a timber frame. The floor of timber boards, the bottom rails and indeed all the timber frame below the window line is badly rotted but the skin is in fair condition. The sidecar has clearly seen a lot of use and has been heavily modified for comfort. It is fitted with a clock, cigarette lighter, radio, lighting and heating for the passenger. Heating was provided by an attachment clamped to the left hand exhaust pipe and fed into the passenger space. The radio and clock are rusted out and all the switches are seized.

The whole body has been lined in a blue velvety material on hardboard although most of that is beyond repair.

|

| The sidecar dashboard with glove box, light, clock, cigarette lighter and radio. |

|

| The heating system. The large part is clamped to the right hand exhaust pipe and connected to a hole in the sidecar skin via a rubber adapter and a flap valve to shut off the air flow. |

One window and the rear panel are decorated with several stickers, shown here, plus one for Britanny Ferries, these appear to predate Eric's ownership.

|

| Stickers for a Dutch campsite, the 1980 Dragon Rally, and the Isle of Man TT. |

|

| Is it one of these? |

|

| This Jaguar (Panther) is bolted on the bonnet. |

As I cleared out the debris from inside it became clear that the framing is in very poor condition, indeed worse than I first thought. The floor of pine boards virtually dropped out when I picked the body up. The bottom rails, also softwood, were also very soft and dropping apart. The further I went the worse it got so that eventually I decided to remove all the skin and get down to the bare framework. Finally the only pieces of timber reusable were the angled door-closing rail and the top, front cross rail.

The roof sheet is of aluminium and non-original; it was presumably added by one of the previous owners. This was fixed with brass screws which all came out fairly easily. as did the stainless screws fixing the aluminium trim. Front and rear panels and trims around the door were held with pop rivets and these were drilled out. The skin had been folded over the timber and fixed with pins during manufacture. These had to be prised out. Eventually I had a pile of panels and the rotten remains of the frame.

The roof sheet is of aluminium and non-original; it was presumably added by one of the previous owners. This was fixed with brass screws which all came out fairly easily. as did the stainless screws fixing the aluminium trim. Front and rear panels and trims around the door were held with pop rivets and these were drilled out. The skin had been folded over the timber and fixed with pins during manufacture. These had to be prised out. Eventually I had a pile of panels and the rotten remains of the frame.

|

| Part way through dismantling/ |

|

| The remains of the frame. |

|

| Panels. |

The Panther chassis that came with the sidecar is fairly rusty but largely sound apart from the plating around the swing arm pivot. This is tricky to repair as welding could affect the rubber bearing for the swing arm. The mudguard is scrap but the tow-bar and spare wheel carrier appear to be ok, albeit home-made.

|

| The Panther Chassis. |

|

Plating by the swing arm bearing rotted out.

|

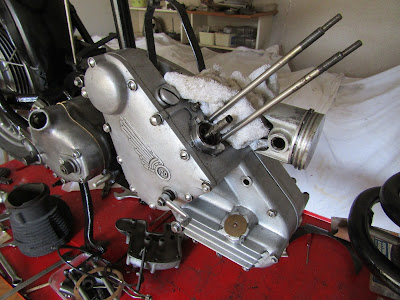

The rebuild is underway.